A small businessman always wants to purchase those things that are good at work and have low costs. Many industries and businesses need a LASER cutter to make their work easy and to save time. The small company continually invests in high-quality LASER, which has a low price. CO2 LASER cutter is an intelligent choice for small businesses. There are many more market options for small businesses, e.g., glow forge 3D LASER printer. Glow forge is best for the overall industry. Dremel Digi lab Lc40 is also a good option.

Small business Explained

One person usually owns a small business. In small companies, the owner operates the business by himself alone. Small business has fewer employees and low revenue and hence low profit and low loss. The owner puts low capital on business and earns a meager profit.

What is a LASER cutter?

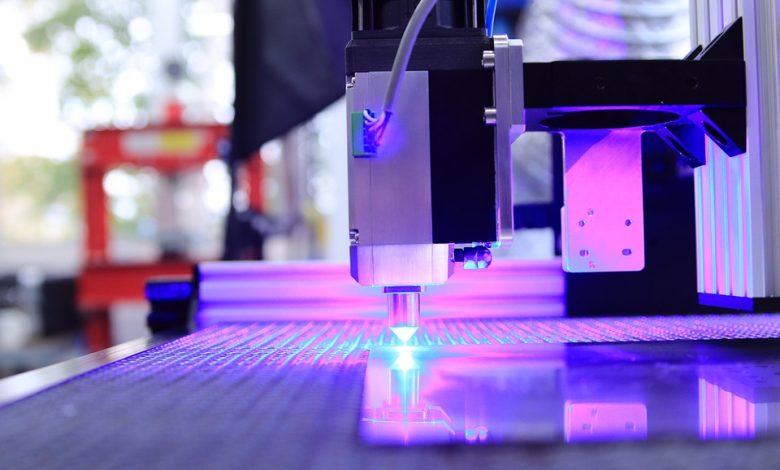

LASER (stands for Light amplification by stimulated emission of radiation) cutter is a machine that uses high power and cuts material with stimulated light, which is very high intensity light. A LASER cutter is a machine that helps design, craft, make patterns, and even cut down materials such as wood, metal, plastic, etc.

Read More: https://postsify.com/how-to-clean-quartz-countertops-all-you-need-to-know/

Uses of LASER cutter

LASER can cut different things like wood, plastic, paper, aluminum, glass, and stone. LASER is also usesfor melting and burning the material. We can change the shape and design of any material and convert the material in our desire form.

Pro’s

LASER cutter is exact in businessman’s work. They use high-power and high-intensity light rays, which can cut and melt the material with precision.

- LASER cutting saves time.

- Laser cutting has near to no waste, and it saves material as compared to manual cutting.

- It can do the job no matter how complex the job is.

- As the handling of the laser cutter is through computer programming so little knowledge about this machine is enough to operate it.

- It consumes low power as compared to manual cutting.

- The lead time of this cutter is shallow, as laser cutters do not need any tool or machine part changing.

Con’s

Besides all of its pros it has some drawbacks also, which are given below,

- Material with high thickness cannot be cut down with laser cutters or require more time for cutting than manual cutting.

- The laser cutter can’t cut higher-density material. For example, we can’t cut glass with a laser.

- Because it cut material with stimulated light, that’s why it burns down the edges of the material.

- The laser cutter has many types that can be used for high, low, and medium businesses. Laser cutters do work with the same size quality and cut material in the desired shape.

Cost of Laser cutting:

- The cost of LASER cutting is according to the material’s thickness and material’s properties.

- The cost of laser cutting also depends on the type of LASER you are using.

Working of LASER cuter:

- Firstly, the power of LASER adjusted according to the sheet’s thickness

- Then the design approved by the designer put into the LASER machine

- Machine cut it in material sheets and placed it on the bench.

- The LASER cuts the material. The emitted light from a resonator; is an airtight glass tube composed of two facing mirrors and filled with diode-activated gases. It’s then emitted light from the cutting head, where light from the resonator is focused light onto a curved lens, where it converges into a single beam.

- The same procedure is used to cut the sheets and convert the materials by melting them.

What are the different types of laser-cutting machines?

Small businessman wants different characteristics in laser cutting machine. They also want a unique and decent LASER cutting machine, which can fit easily in their workplace, home, or anywhere else. Every business can make an early and instant profit and get back the money invested in purchasing the machine from their LASER cutting machine. There are many types of LASER cutting machines which are undermentioned:

Co2 LASER cutter

These LASERs are used primarily on small businesses because these are extra efficient at a low price CO2 LASER can cut thick material with the same fiber power. CO2 is a mixture of carbon and oxygen. The wavelength of CO2 is 10.6mm.

Glow forge plus 3D LASER printer

Glow forge is the best choice for small businesses. Glow forge looks cool in offices of small businesses, studios, or commercial properties. This LASER also saves your time because a small businessman has no spare time to waste.

Advantagesof 3D LASER printer

The use of this machine is effortless. You draw your design with a pencil or make a computer drawing. Whatever you want, put this design into the machine and press the button. The result is right in front of you. This type of LASER has unique cameras to scan your designs.

Orion Motor Tech 40W CO2 LASER

Orion motor tech 40W LASER uses more power than others. Glow forge and this LASER have a more negligible difference in prices. The quality of work of this LASER is relatively better than others. This LASER cutter comes with its software. It also has a cooling system to save from overheating. It has a digital panel display to help in placing your material. This LASER is mainly used for cutting wood, glass, paper, plastic, rubber, fabrics, etc.

Dremel Digilab Lc40

This LASER can perfectly fit on a desktop or a working desk. This LASER has many features. It is consistent in work and gives impressive results with safety. This LASER is also certified by market users.

Best wood LASER cutter for small business

Bobs CNC Evolution 3 CNC Router kit

This type of LASER cutter has fantastic technology for more accessible work. A LASER cutter works without LASER, so the Bob CNC Evolution is the best choice. It consumes 600-watt power. It also works differently from other LASERs—the LASER beams of this cutter drill into the material instead of burnings it. And cut according to our programmed design. Typically, other LASERs cut the material from one side or two sides, but the CNC cutter cuts three sides of the material in depth. This cutter is cheaper as compared to other cutters.

Conclusion

To sell their wares and personalize their crafts, small business owner wants to be able to do so. In addition, you can convey your values, design style, and personality on your products, which will attract new clients seeking unique gifts.

Apart from this, if you’re interested to know about LMS- Learning Management System for Schools in 2022 then please visit our Tech category.