Find The Best Water Jet For High Pressure in The Industry

With years of massive research and studies, we produce high end water jet ejectors for wide range of applications in industrial products.These ejectors are developed and manufactured by using hybrid vacuum injection systems supported by a complete functionalities and system warranty for global usage by maintaining high quality engineering, service, and technical support.

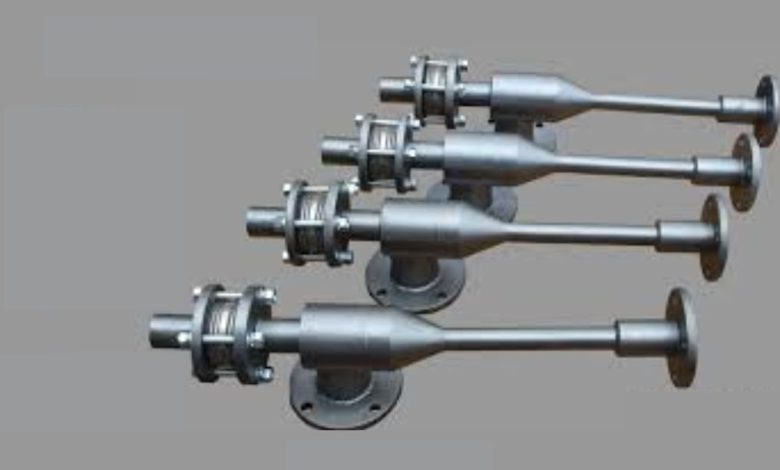

Due to widespread usage in many industrial plants they are available in a variety of sizes and specifications depending on the applications.

Water jet ejector possesses four main parts: an inlet casing, a suction nozzle, a venturi for exerting pressure in a mixing chamber for fluids and a diffuser. In addition to all of these they are fabricated with spindles for holding and exact positioning of objects.

Water Jet Ejectors are highly designed with morderised technologies and offer many advantages when compared with other vacuum producing pumps, such as usual mechanically operated pumps like liquid ring compressor Pumps, Rotational turbines or conventional screw type pumps. The ejectors create vacuum by high pressure medium like water or steam, the higher grade kinetic energy developed in the mixing chamber, where vapors or other liquids are discharged then the resultant mixture is produced against a counter pressure.

Our Water Jet Products:

Depending on various industrial purposes, using water jet ejector technology, we implemented the following product for specific functions. Marine Water Ejectors, single and multistage ejectors, steam jet thermal compressors, cryogenic equipments, static mixers, steam surface condensers, feed water heater, vacuum water ejectors, steam desuperheaters etc

They are easy to install and adapt to the surroundings. These ejectors have the potential to support large volumes at larger vacuum levels and are effective to contribute to boost operational standards and functional effectiveness.

Advantages of Water Jet Ejectors are

- Highly durable, economical and user friendly.

- Require less Maintenance and Repair for wear and tear of parts

- They are custom designed as per the requirements and standards of industrial pumps and its functionalities.

- Built with resilient materials and highly potential in operation

- Noiseless moving parts and easy mechanisms make them function efficiently and effectively.

- Corrosion resistant built with exotic materials like graphite and titanium

- No additional energy required except (motive fluid used)

- Ideal for holding large and contaminated pressure loads.

- Robust model to adapt the climatic conditions

- Safe to use and maintain in hazardous industrial plant, can be able to withstand high electricity and power

Our production-friendly units contribute significantly to the lesser usage of plastics, very low to nil Carbon Dioxide emissions, and zero wastages. We take utmost care in design, engineering, research, packing, delivery and work towards a zero defect product.

Specified usage of water jet ejectors in daily use and diverse industrial applications

- In recent years steam vacuum refrigeration systems have become extremely popular due to its wide range of applications.

- have the ability to carry out a variety of high pressure water jetting techniques consisting of industrial tasks which consume lots of time and energy industrial cleaning, concrete removal, and surface preparation.

- Water storage in tanks and plants

- Used in plants for wastewater treatment.

- Supply of water for farming, irrigation and cultivation of crops

- For the preparation of industrial chemicals like polyelectrolyte production.

We produce, design and generate customized variants of water jet ejectors and a leading potential supplier of water jet ejectors throughout the world markets. They are ideal for the oil and natural gas, petrochemical, electrical, hydel power, textile and paper industries.

The manufacturing units are properly equipped with modern technology and designing of customized products. The production units are provided with process vacuum, heat transfer, steam conditioning equipment by stringent jet flow technologies to build the most advanced water ejectors for process engineering through fluid flow techniques.

Quality And Standards

Regular check up of raw materials, production techniques are thoroughly viewed by the Quality assurance department from time to time.

Valuable feedback from customers and acknowledgement of our work inspire us to work harder and continue to improvise.

Mission

Our mission is to supply quality ejectors to the world’s major producer, retailer and suppliers of modified Ejectors variations and to deliver more effective, trusted and innovative products to companies.